Science

Innovative Composite Material Developed from Egg Whites Enhances Heat Dissipation

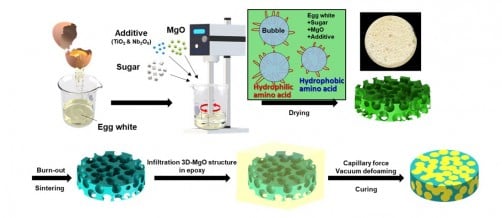

A research team led by Dr. Hyun-Ae Cha from the Korea Institute of Materials Science (KIMS) has created a new high-performance composite material that addresses the pressing need for effective heat management in electronic devices. The innovative material, developed using a protein foaming process inspired by egg whites, significantly enhances thermal conductivity while being both eco-friendly and cost-effective.

The new composite features a three-dimensional magnesium oxide (MgO) structure that establishes efficient thermal pathways, enabling rapid heat transfer. In testing, this material exhibited a thermal conductivity up to 2.6 times higher than traditional heat-dissipating composites.

Meeting the Demands of Modern Technology

As electronic devices become increasingly compact and powerful, they generate more heat, necessitating advanced thermal management solutions. In electric vehicles (EVs), inadequate battery cooling can lead to performance issues and serious safety risks, including fires or explosions. The pivotal component in these thermal management systems is the Thermal Interface Material (TIM), which is crucial for efficient heat dissipation.

Conventional TIMs typically consist of thermally conductive fillers mixed into a polymer matrix. This traditional method often results in randomly dispersed fillers, which can disrupt thermal pathways and hinder performance. Increasing the filler content may enhance thermal conductivity but can complicate processing and elevate costs, limiting scalability.

To overcome these challenges, the KIMS research team utilized a novel protein foaming technique. This process enables the creation of a densely interconnected, three-dimensional network of particles, allowing for continuous thermal pathways that enhance heat transfer. By leveraging the properties of egg-white proteins that expand under high temperatures, the team successfully produced a composite material with a thermal conductivity of 17.19 W/m·K.

Implications for Industry and Future Applications

The newly developed composite not only surpasses the thermal conductivity of commonly used aluminum oxide (Al2O3) but also outperforms nitride-based heat-dissipating materials. By combining the MgO material with epoxy resin, a polymer that improves adhesion, the team has created a composite that is ready for real-world applications.

The implications of this research are significant. The use of this lightweight and low-cost composite is expected to enhance the performance and stability of various high-heat generating devices, including electronic equipment, semiconductor packages, EV batteries, 5G communication devices, and high-performance servers.

Korea’s domestic market for TIMs is estimated to exceed KRW 200 billion annually, yet it heavily relies on imports for these materials. The commercialization of this innovative technology is anticipated to strengthen Korea’s technological independence in the thermal management sector.

Dr. Cha remarked, “Through the protein foaming–based process, we can produce high–thermal–conductivity materials in an eco-friendly and cost-effective way.” She emphasized that this study serves as a compelling demonstration of the potential for developing lightweight, high-performance heat-dissipating materials.

This research was funded by the Nano Materials Technology Development Program of the National Research Foundation of Korea (NRF). The findings were published on May 28, 2023, in the prestigious journal Advanced Science, where it was selected as the cover article for Volume 12, Issue 33.

-

Science2 months ago

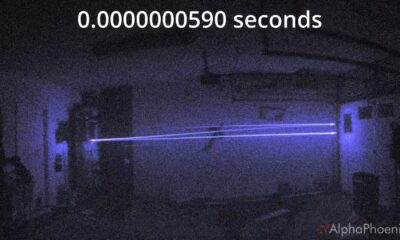

Science2 months agoInventor Achieves Breakthrough with 2 Billion FPS Laser Video

-

Health2 months ago

Health2 months agoCommunity Unites for 7th Annual Into the Light Walk for Mental Health

-

Top Stories2 months ago

Top Stories2 months agoCharlie Sheen’s New Romance: ‘Glowing’ with Younger Partner

-

Entertainment2 months ago

Entertainment2 months agoDua Lipa Aces GCSE Spanish, Sparks Super Bowl Buzz with Fans

-

Health2 months ago

Health2 months agoCurium Group, PeptiDream, and PDRadiopharma Launch Key Cancer Trial

-

Entertainment2 months ago

Entertainment2 months agoMother Fights to Reunite with Children After Kidnapping in New Drama

-

Top Stories2 months ago

Top Stories2 months agoFormer Mozilla CMO Launches AI-Driven Cannabis Cocktail Brand Fast

-

World2 months ago

World2 months agoIsrael Reopens Rafah Crossing After Hostage Remains Returned

-

Business2 months ago

Business2 months agoTyler Technologies Set to Reveal Q3 Earnings on October 22

-

Health2 months ago

Health2 months agoNorth Carolina’s Biotech Boom: Billions in New Investments

-

World2 months ago

World2 months agoR&B Icon D’Angelo Dies at 51, Leaving Lasting Legacy

-

Entertainment2 months ago

Entertainment2 months agoRed Sox’s Bregman to Become Free Agent; Tigers Commit to Skubal