Science

AI Revolutionizes Warehouses: 60% Adoption Rate Unveiled

A recent study conducted by Mecalux and the MIT Intelligent Logistics Systems Lab reveals that artificial intelligence (AI) has become a cornerstone of modern warehouse operations, with approximately 60 percent of warehouses now incorporating AI technologies. This comprehensive research, which surveyed more than 2,000 logistics leaders across 21 countries, highlights the rapid adoption of automation and AI, particularly as retailers prepare for the annual surge in demand during the Black Friday shopping season.

The findings indicate that AI and machine learning have transitioned from being experimental tools to essential components that drive productivity and enhance operational accuracy. Notably, over 90 percent of warehouses reported utilizing some form of AI or advanced automation, showcasing a significant maturity level across the sector. More than half of the organizations surveyed indicated they operate at advanced or fully automated maturity levels, particularly among larger companies managing complex logistics networks.

As AI becomes integral to daily operations, it plays a crucial role in various tasks, including order picking, inventory optimization, equipment maintenance, labor planning, and safety monitoring. According to Javier Carrillo, CEO of Mecalux, “The data show that intelligent warehouses outperform not only in volume and accuracy, but in adaptability.” He emphasized that companies investing in AI are not just achieving faster operations but are also becoming more resilient and predictable in the face of market volatility.

The study further reveals that investments in AI are yielding quicker returns than anticipated, with most businesses allocating between 11 percent and 30 percent of their warehouse technology budgets to AI and machine learning initiatives. The typical payback period for these investments is reported to be between two and three years, driven by improvements in inventory accuracy, operational throughput, labor efficiency, and a reduction in errors. This shift marks a transition from exploratory spending to a focus on developing long-term capabilities.

Despite these advancements, organizations face challenges in scaling AI across their operations. Dr. Matthias Winkenbach, Director of the MIT ILS Lab, points out that the integration of people, data, and analytics into existing systems remains a significant hurdle. Key barriers include the need for technical expertise, effective system integration, quality data management, and the costs associated with implementation. Nevertheless, many companies report solid foundations in data management and project execution, identifying better tools, clearer strategic roadmaps, expanded budgets, and enhanced internal expertise as facilitators for continued AI adoption.

Importantly, the report challenges ongoing concerns regarding automation displacing human workers. Instead of reducing job opportunities, AI is enhancing productivity and job satisfaction in the workforce. More than 75 percent of organizations surveyed observed increased employee productivity and satisfaction following the implementation of AI tools, while over half reported expanding their workforce. New roles are emerging, including positions for AI and machine learning engineers, automation specialists, process improvement experts, and data scientists. These developments indicate that intelligent automation is broadening, rather than diminishing, the human role within warehouse operations.

Looking forward, nearly every company surveyed plans to expand its use of AI in the next two to three years. An overwhelming 87 percent expect to increase their AI budgets, and 92 percent are currently implementing or planning new AI projects. The report identifies decision-making technologies, particularly generative AI, as the next frontier in warehouse operations. Businesses recognize generative AI as a vital tool for today’s logistics, with applications ranging from automated documentation to warehouse layout optimization and process flow design.

As these capabilities evolve, AI is poised to help a growing number of warehouses transition from predictive insights to automated actions. “Traditional machine learning is great at predicting problems, but generative AI actually helps you engineer the solution,” explains Dr. Winkenbach. “That’s why companies see it as the biggest value generator in the warehouse today.”

The study underscores that as the logistics sector approaches its busiest season, the warehouses supporting Black Friday orders are not merely automating processes but are evolving into intelligent systems. With AI enhancing performance and supporting workers, the logistics industry is set for even more profound integration of data and decision-making capabilities in the coming years.

-

Science1 month ago

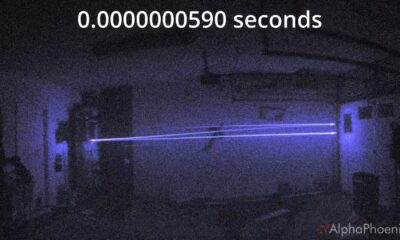

Science1 month agoInventor Achieves Breakthrough with 2 Billion FPS Laser Video

-

Health2 months ago

Health2 months agoCommunity Unites for 7th Annual Into the Light Walk for Mental Health

-

Top Stories2 months ago

Top Stories2 months agoCharlie Sheen’s New Romance: ‘Glowing’ with Younger Partner

-

Entertainment2 months ago

Entertainment2 months agoDua Lipa Aces GCSE Spanish, Sparks Super Bowl Buzz with Fans

-

Entertainment2 months ago

Entertainment2 months agoMother Fights to Reunite with Children After Kidnapping in New Drama

-

Top Stories1 month ago

Top Stories1 month agoFormer Mozilla CMO Launches AI-Driven Cannabis Cocktail Brand Fast

-

Health2 months ago

Health2 months agoCurium Group, PeptiDream, and PDRadiopharma Launch Key Cancer Trial

-

Business2 months ago

Business2 months agoTyler Technologies Set to Reveal Q3 Earnings on October 22

-

World2 months ago

World2 months agoIsrael Reopens Rafah Crossing After Hostage Remains Returned

-

Health2 months ago

Health2 months agoNorth Carolina’s Biotech Boom: Billions in New Investments

-

World2 months ago

World2 months agoR&B Icon D’Angelo Dies at 51, Leaving Lasting Legacy

-

Entertainment2 months ago

Entertainment2 months agoRed Sox’s Bregman to Become Free Agent; Tigers Commit to Skubal