Science

Automation Revolutionizes Factory Processes: Welding, Painting, and Dispensing

Manufacturers across the globe are experiencing a significant transformation in factory processes due to advancements in automation technologies. Key sectors such as automotive, aerospace, heavy machinery, and industrial fabrication are increasingly adopting smarter robotic systems to enhance workflow efficiency. This shift is largely driven by global competition, labor shortages, and escalating quality expectations. The results are becoming evident through improved process stability, faster production times, and a notable reduction in operator exposure to hazardous conditions.

Advancements in Robotic Welding

Robotic welding has historically faced challenges related to variability, including part-to-part dimensional differences and heat distortion. The demand for skilled welders is intensifying these issues. Recent technological advancements in robotic welding have significantly improved the ability to adapt to these variations.

For instance, the Fronius TPS/i Robotics system employs high-speed laser seam-tracking sensors that automatically adjust the weld torch’s position and speed in real time, compensating for joint variations. Similarly, Lincoln Electric’s HyperFill system integrates AI-driven weld-parameter optimization, analyzing data to enhance weld quality.

Moreover, Yaskawa’s WeldPlus architecture connects robots with digital welding power sources, synchronizing their movements to minimize arc-start delays and improve penetration stability. Collaborative welding arms are now making their way into high-mix, low-volume environments, allowing for rapid adaptations without halting production. For example, Universal Robots’ UR10 combined with the ReadyArc welding package enables quick jig changes, enhancing flexibility on the factory floor.

Transforming Robotic Painting and Dispensing

The painting process, known for its regulatory challenges due to chemical exposure and VOC emissions, is also undergoing a technological overhaul. Modern systems utilize advanced rotary atomizers and electrostatic spray guns to achieve fine droplet control, improving transfer efficiency and reducing waste. The ABB RB1000 rotary atomizer exemplifies this with its high-precision electrostatic charging capabilities.

Robotic paint cells now incorporate 3D cameras that dynamically adjust paths for optimal application, as seen in Fanuc’s robotic paint cells. These robots maintain ideal orientations even for complex shapes, ensuring consistent finishes. In addition, Kuka’s AI-powered quality inspection platform identifies defects in real time, automatically adjusting atomizer settings to enhance uniformity.

In the area of dispensing, maintaining the quality of adhesive beads is critical. Nordson EFD’s Precision Mix and Dispense systems utilize feedback-controlled metering to ensure consistent bead quality, even with variable material viscosity. The integration of laser profilometers into systems like Atlas Copco’s EBB enables immediate correction of flow errors, enhancing seal quality.

Technology is also advancing the use of digital twins and offline programming software, which allow for virtual testing of robotic cells. This approach significantly reduces commissioning time and optimizes production processes before physical implementation.

As the demand for skilled labor continues to shift, the integration of robotics in welding, painting, and dispensing is making these roles safer and more appealing. Workers are increasingly taking on technical responsibilities, moving away from hazardous tasks that involve fumes and heat.

Overall, the advancements in robotic welding, painting, and dispensing mark a new era defined by adaptive sensing, AI optimization, and integrated systems. Manufacturers investing in these technologies are witnessing substantial improvements in quality and safety, paving the way for a more resilient production environment capable of handling increasing complexity with fewer skilled workers.

-

Science1 month ago

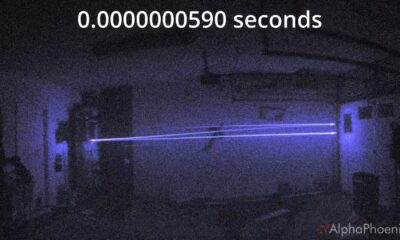

Science1 month agoInventor Achieves Breakthrough with 2 Billion FPS Laser Video

-

Health2 months ago

Health2 months agoCommunity Unites for 7th Annual Into the Light Walk for Mental Health

-

Top Stories2 months ago

Top Stories2 months agoCharlie Sheen’s New Romance: ‘Glowing’ with Younger Partner

-

Entertainment2 months ago

Entertainment2 months agoDua Lipa Aces GCSE Spanish, Sparks Super Bowl Buzz with Fans

-

Entertainment2 months ago

Entertainment2 months agoMother Fights to Reunite with Children After Kidnapping in New Drama

-

Top Stories2 months ago

Top Stories2 months agoFormer Mozilla CMO Launches AI-Driven Cannabis Cocktail Brand Fast

-

Health2 months ago

Health2 months agoCurium Group, PeptiDream, and PDRadiopharma Launch Key Cancer Trial

-

Business2 months ago

Business2 months agoTyler Technologies Set to Reveal Q3 Earnings on October 22

-

World2 months ago

World2 months agoIsrael Reopens Rafah Crossing After Hostage Remains Returned

-

Health2 months ago

Health2 months agoNorth Carolina’s Biotech Boom: Billions in New Investments

-

Entertainment2 months ago

Entertainment2 months agoRed Sox’s Bregman to Become Free Agent; Tigers Commit to Skubal

-

World2 months ago

World2 months agoR&B Icon D’Angelo Dies at 51, Leaving Lasting Legacy