Science

New Graphene-Enhanced Plastic Strengthens Auto Parts by 20%

A groundbreaking development in automotive materials has emerged as researchers successfully enhanced glass-filled polypropylene with graphene, resulting in a new product known as Gratek. This innovative substance is reported to be 20% stronger and 18% lighter than traditional plastic, making it an exciting advancement in the automotive sector.

Graphene, often referred to as a “wonder material,” consists of one-atom-thick sheets of carbon atoms arranged in a honeycomb structure. It stands out as the strongest known human-made material, characterized by its flexibility, stretchability, and exceptional thermal and electrical conductivity. The research spearheaded by Nello David Sansone, a post-doctoral researcher at the University of Toronto, focused on integrating graphene nanoplatelets into glass-filled polypropylene to enhance its properties.

Through a collaboration with Axiom Group, an auto parts manufacturer, Sansone developed a proprietary technique that prevents the graphene from clustering during processing. Previous attempts to integrate graphene into automotive components had led to mechanical failures due to concentrated stress. By ensuring that the nanoplatelets bond exclusively to the glass fibers within the polypropylene matrix, Sansone effectively strengthened the material without compromising its integrity.

The result is Gratek, a composite material that is less than 1% graphene overall. Its enhanced strength allows for a reduction in the amount of glass fibers needed, contributing to the overall weight reduction. Additionally, the lower glass content in Gratek reduces wear on manufacturing equipment used for cutting and drilling, further optimizing production processes.

While Gratek’s performance is promising, it does come with a limitation: its color is restricted to black due to the graphene content. To address this challenge, Sansone has also developed Clatek, which substitutes graphene with clay-based halloysite nanotubes. Clatek offers similar performance characteristics to Gratek but is white in color, allowing for easier dyeing and painting options.

The commercial potential for these materials is significant. Gratek is expected to be contracted by a major automobile manufacturer before the end of 2023, while Clatek is projected to become commercially available within the next two years. “It has shown real potential to make vehicles lighter, safer, and more sustainable,” Sansone stated.

In addition to his work on Gratek and Clatek, Sansone is pursuing further innovations through his startup, NanoMorphix. He is currently focused on commercializing AegisX, an advanced material formulation intended for use in military, defense, aerospace, and personal protection sectors. His contributions to materials science have been recognized with an award from Mitacs, a government-funded organization in Canada dedicated to fostering technical innovation.

As the automotive industry increasingly seeks to adopt lighter and more sustainable materials, the developments from Sansone and his team could pave the way for a new era in vehicle manufacturing, enhancing performance while reducing environmental impact.

-

Science1 month ago

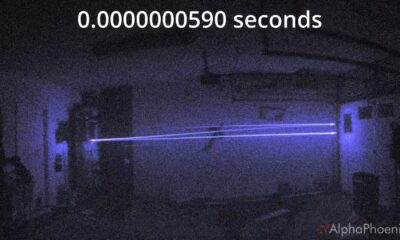

Science1 month agoInventor Achieves Breakthrough with 2 Billion FPS Laser Video

-

Health2 months ago

Health2 months agoCommunity Unites for 7th Annual Into the Light Walk for Mental Health

-

Top Stories2 months ago

Top Stories2 months agoCharlie Sheen’s New Romance: ‘Glowing’ with Younger Partner

-

Entertainment2 months ago

Entertainment2 months agoDua Lipa Aces GCSE Spanish, Sparks Super Bowl Buzz with Fans

-

Entertainment2 months ago

Entertainment2 months agoMother Fights to Reunite with Children After Kidnapping in New Drama

-

Top Stories1 month ago

Top Stories1 month agoFormer Mozilla CMO Launches AI-Driven Cannabis Cocktail Brand Fast

-

Health2 months ago

Health2 months agoCurium Group, PeptiDream, and PDRadiopharma Launch Key Cancer Trial

-

Business2 months ago

Business2 months agoTyler Technologies Set to Reveal Q3 Earnings on October 22

-

World2 months ago

World2 months agoIsrael Reopens Rafah Crossing After Hostage Remains Returned

-

Health2 months ago

Health2 months agoNorth Carolina’s Biotech Boom: Billions in New Investments

-

World2 months ago

World2 months agoR&B Icon D’Angelo Dies at 51, Leaving Lasting Legacy

-

Entertainment2 months ago

Entertainment2 months agoRed Sox’s Bregman to Become Free Agent; Tigers Commit to Skubal