Science

Researchers Innovate Battery Electrode Manufacturing Process

A collaborative research effort led by Dr. Gyujin Song from the Korea Institute of Energy Research (KIER), alongside Dr. Kwon-Hyung Lee from the University of Cambridge and Professor Tae-Hee Kim from the University of Ulsan, has resulted in a groundbreaking dry-process technology for manufacturing secondary battery electrodes. This innovative approach addresses significant limitations found in traditional electrode fabrication methods.

The newly developed technology creates a dual-fibrous structure within the electrode, forming both thin “thread-like” and thick “rope-like” fibers. This dual-fiber architecture effectively tackles the common issues of low mixing strength and performance degradation typically associated with conventional dry processes. While traditional electrode manufacturing methods are categorized into wet and dry processes, the wet method predominantly relies on toxic solvents that raise environmental concerns and increase production costs.

The conventional wet process employs a binder dissolved in a solvent to facilitate the uniform mixing of electrode materials. However, this approach leads to environmental burdens due to solvent usage and results in lengthy drying times. Consequently, there is a growing interest in dry-process technologies that eliminate solvent use. The dry method reduces environmental pollution and energy consumption, but it has traditionally been limited in the range of binder materials available, primarily utilizing polytetrafluoroethylene (PTFE), a material recognized for its heat and chemical resistance.

To enhance the structural integrity of dry electrodes, the research team maintained the use of PTFE but innovated the process by which the binder is added. They developed a multi-step approach that separates binder addition into two distinct stages. Initially, a small amount of binder is introduced, creating a fine, thread-like fibrous network that connects the active material and the conductive additive. Subsequently, in a second stage, the remaining binder is added, forming a robust rope-like fiber structure while preserving the initial fibrous network.

This advanced structure ensures uniform dispersion of the electrode materials, enhancing the electrochemical reactions and overall battery performance. The thick, rope-like fibers significantly increase the electrode’s strength and mechanical stability, vital for mass production. Analysis through electrochemical reaction-resistance mapping demonstrated that the electrodes exhibit fast and uniform reaction kinetics, minimizing energy loss during operation and extending the overall lifespan of the batteries.

In performance tests, the newly developed dry electrode achieved a remarkable areal capacity of 10.1 mAh/cm2. A pouch-type lithium metal anode cell utilizing this electrode reached an energy density of 349 Wh/kg, representing an increase of approximately 40% compared to conventional electrodes, which typically reach around 250 Wh/kg. Additionally, a pouch cell with a graphite anode displayed an energy density of 291 Wh/kg, approximately 20% higher than wet-process cells under similar conditions.

Dr. Song emphasized the significance of this research, stating, “This study is highly significant in that we have established an original process technology capable of simultaneously resolving the two core challenges of dry electrodes: electrochemical uniformity and mechanical durability.” He further noted the potential implications for the secondary battery industry, particularly in applications requiring high energy density, such as electric vehicles and energy storage systems.

This research was supported by the Ministry of Science and ICT under its “Global TOP Research Program” and “Creative Allied Project.” The findings were published in the September 2023 issue of Energy & Environmental Science, a leading journal in the energy and environmental fields.

-

Science2 months ago

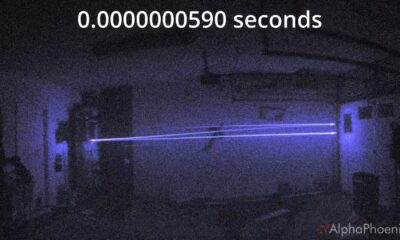

Science2 months agoInventor Achieves Breakthrough with 2 Billion FPS Laser Video

-

Health2 months ago

Health2 months agoCommunity Unites for 7th Annual Into the Light Walk for Mental Health

-

Top Stories2 months ago

Top Stories2 months agoCharlie Sheen’s New Romance: ‘Glowing’ with Younger Partner

-

Entertainment2 months ago

Entertainment2 months agoDua Lipa Aces GCSE Spanish, Sparks Super Bowl Buzz with Fans

-

Health2 months ago

Health2 months agoCurium Group, PeptiDream, and PDRadiopharma Launch Key Cancer Trial

-

Top Stories2 months ago

Top Stories2 months agoFormer Mozilla CMO Launches AI-Driven Cannabis Cocktail Brand Fast

-

Entertainment2 months ago

Entertainment2 months agoMother Fights to Reunite with Children After Kidnapping in New Drama

-

World2 months ago

World2 months agoIsrael Reopens Rafah Crossing After Hostage Remains Returned

-

Business2 months ago

Business2 months agoTyler Technologies Set to Reveal Q3 Earnings on October 22

-

World2 months ago

World2 months agoR&B Icon D’Angelo Dies at 51, Leaving Lasting Legacy

-

Health2 months ago

Health2 months agoNorth Carolina’s Biotech Boom: Billions in New Investments

-

Health2 months ago

Health2 months agoYouTube Launches New Mental Health Tools for Teen Users