Top Stories

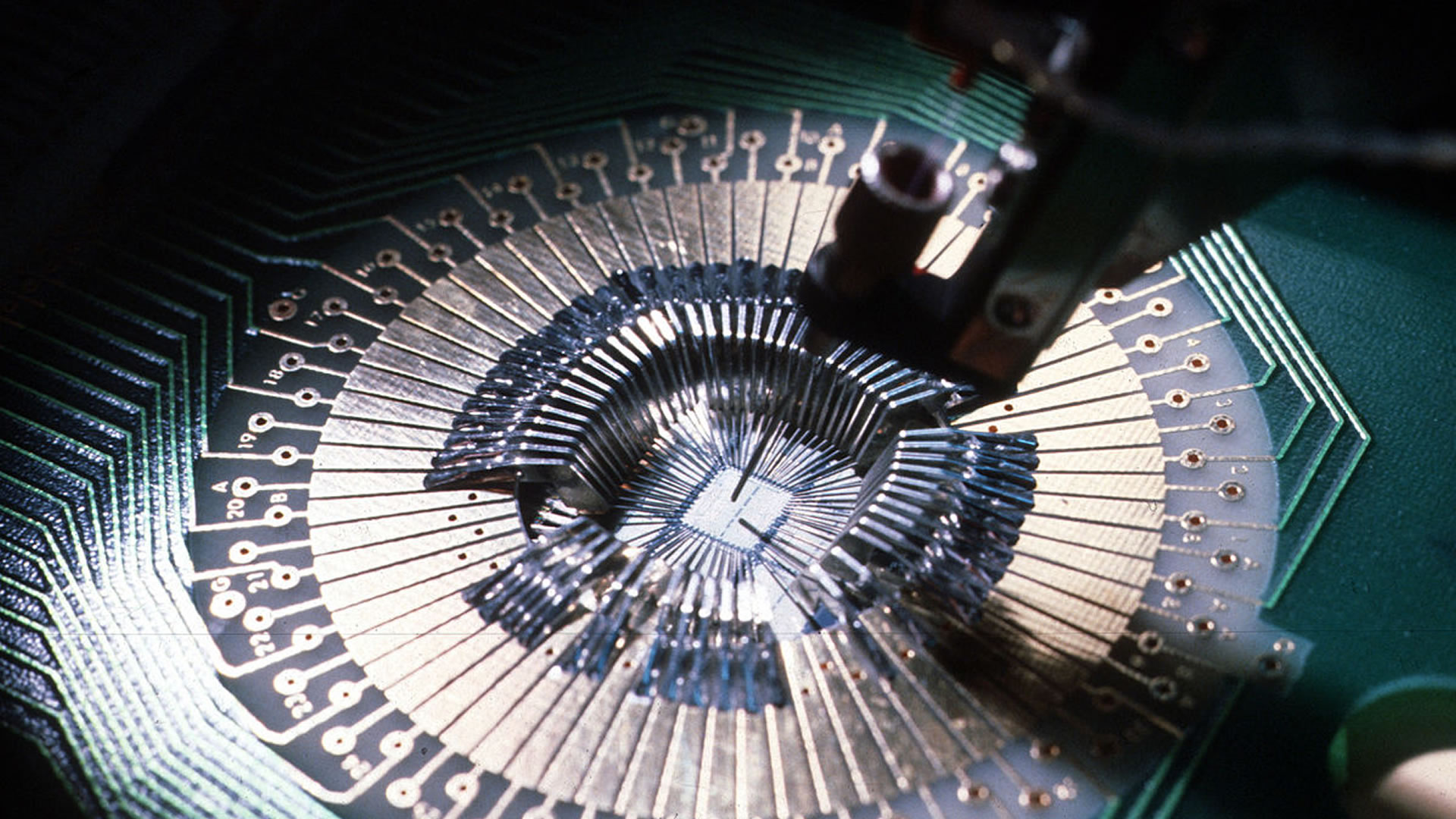

BREAKING: China Slashes Microchip Defects by 99% with New Tech

UPDATE: Chinese researchers have just announced a groundbreaking innovation that could revolutionize microchip production by reducing defects by an astonishing 99%. The team from Peking University, Tsinghua University, and HKU has developed a cutting-edge cryogenic technique capable of identifying the sources of manufacturing flaws in semiconductors.

This urgent breakthrough comes at a crucial time for the semiconductor industry, where even minor defects can lead to significant financial losses. Currently, during the photolithography phase of chip production, imperfections can arise due to clumping of photoresist materials, causing irreparable damage to circuits. With chips now being produced at 5-nanometer nodes, a particle just 30 nanometers wide can render an entire microchip useless.

For years, manufacturers struggled to monitor the photolithography process, likening it to a “black box.” However, Professor Peng Hailin and his team have turned this around by utilizing a technique known as cryo-electron tomography, or cryo-ET. This method freezes the chemical processes in real-time at an incredible –175°C (32°F), allowing for a detailed 3D visualization of the photoresist behavior during development.

Their findings are remarkable: approximately 70% of photoresist molecules do not dissolve properly and instead accumulate at the air-liquid interface, leading to defects when the wafer is rinsed. By understanding these interactions, the researchers implemented two effective modifications to the existing chip fabrication process. They recommend slightly increasing the baking temperature post-exposure to prevent polymer tangling and adjusting the rinse process to eliminate problematic clumps.

The results speak for themselves. In tests on 12-inch (30.5 cm) wafers, defect rates plummeted by over 99%, achieving near-perfect lithography quality. This breakthrough not only promises to enhance the reliability of semiconductor manufacturing in China but also positions the country as a formidable player in the global tech landscape.

As authorities and industry leaders take notice, the implications of this technological advancement could reach far beyond China’s borders. The potential for improved microchip production could bolster economies globally and address the ongoing semiconductor shortages that have impacted various sectors.

Analysts and experts will be watching closely to see how quickly manufacturers can integrate this innovative technology into their production lines. The developments from Professor Peng’s team could mark a pivotal shift in the semiconductor industry, making it a must-share story for anyone invested in technology and manufacturing.

Stay tuned for more updates as this story develops and watch for further reactions from industry leaders regarding this significant advancement in microchip production technology.

-

Science2 weeks ago

Science2 weeks agoInventor Achieves Breakthrough with 2 Billion FPS Laser Video

-

Top Stories3 weeks ago

Top Stories3 weeks agoCharlie Sheen’s New Romance: ‘Glowing’ with Younger Partner

-

Business3 weeks ago

Business3 weeks agoTyler Technologies Set to Reveal Q3 Earnings on October 22

-

Entertainment3 weeks ago

Entertainment3 weeks agoDua Lipa Aces GCSE Spanish, Sparks Super Bowl Buzz with Fans

-

Health3 weeks ago

Health3 weeks agoCommunity Unites for 7th Annual Into the Light Walk for Mental Health

-

Health3 weeks ago

Health3 weeks agoCurium Group, PeptiDream, and PDRadiopharma Launch Key Cancer Trial

-

World3 weeks ago

World3 weeks agoR&B Icon D’Angelo Dies at 51, Leaving Lasting Legacy

-

Entertainment3 weeks ago

Entertainment3 weeks agoRed Sox’s Bregman to Become Free Agent; Tigers Commit to Skubal

-

Entertainment3 weeks ago

Entertainment3 weeks agoMother Fights to Reunite with Children After Kidnapping in New Drama

-

Health3 weeks ago

Health3 weeks agoNorth Carolina’s Biotech Boom: Billions in New Investments

-

Science3 weeks ago

Science3 weeks agoNorth Carolina’s Biotech Boom: Billions Invested in Manufacturing

-

Top Stories3 weeks ago

Top Stories3 weeks agoDisney+ Launches Chilling Classic ‘Something Wicked’ Just in Time for October