Health

Researchers Transform Teflon Waste into Toothpaste Fluoride

A recent breakthrough by researchers in the United Kingdom offers a new method to recycle Teflon, transforming it into fluoride used in toothpaste and drinking water. This innovative approach addresses the environmental challenges posed by Teflon, which has been difficult to dispose of safely since its introduction by DuPont in 1938. The findings were published on October 22, 2023, in the Journal of the American Chemical Society.

Teflon, or Polytetrafluoroethylene (PTFE), is known for its nonstick properties and is widely used in cookware, lubricants, and medical devices. However, it is also part of the poly- and perfluoroalkyl substances (PFAs) family, which have been linked to various environmental and health concerns. When incinerated, Teflon releases harmful “forever chemicals” that persist in the environment. Previous attempts to tackle Teflon waste have included complex chemical additives and energy-intensive treatments.

Researchers from the University of Birmingham and Newcastle University have developed a simpler and more cost-effective method using mechanochemistry. This technique leverages mechanical energy, rather than heat, to induce chemical reactions, making it appealing to environmental advocates. According to Erli Lu, a co-author of the study, “Our approach is simple, fast, and uses inexpensive materials.”

The process begins by placing fragments of sodium metal and Teflon waste into a sealed steel container known as a ball mill. The ball mill grinds the materials together, breaking the strong carbon-fluorine bonds in Teflon. This reaction occurs at room temperature and results in the formation of harmless carbon and stable sodium fluoride, which is widely used in dental care products and water fluoridation.

Co-author Dominik Kubicki explained the significance of their findings: “We used advanced solid-state Nuclear Magnetic Resonance spectroscopy to look inside the reaction mixture at the atomic level. This allowed us to prove that the process produces clean sodium fluoride without any by-products.” The resulting sodium fluoride is so pure that it can be used directly without further purification.

Beyond toothpaste and drinking water, this method may also allow for the production of other fluorine-containing compounds that are valuable in pharmaceuticals and medical diagnostics. The researchers envision their technique as a pathway toward a fluorine circular economy, where useful compounds are extracted from waste rather than disposed of or incinerated.

Lu highlighted the broader implications of this research, stating, “We hope it will inspire further work on reusing other kinds of fluorinated waste and help make the production of vital fluorine-containing compounds more sustainable.” As environmental concerns continue to grow, this innovative recycling method could pave the way for more sustainable practices in managing chemical waste.

-

Science3 days ago

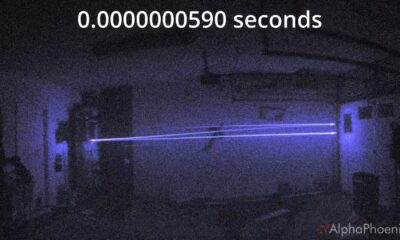

Science3 days agoInventor Achieves Breakthrough with 2 Billion FPS Laser Video

-

Top Stories1 week ago

Top Stories1 week agoCharlie Sheen’s New Romance: ‘Glowing’ with Younger Partner

-

Entertainment1 week ago

Entertainment1 week agoDua Lipa Aces GCSE Spanish, Sparks Super Bowl Buzz with Fans

-

Business1 week ago

Business1 week agoTyler Technologies Set to Reveal Q3 Earnings on October 22

-

World1 week ago

World1 week agoR&B Icon D’Angelo Dies at 51, Leaving Lasting Legacy

-

Science1 week ago

Science1 week agoNorth Carolina’s Biotech Boom: Billions Invested in Manufacturing

-

Health1 week ago

Health1 week agoCurium Group, PeptiDream, and PDRadiopharma Launch Key Cancer Trial

-

Health1 week ago

Health1 week agoCommunity Unites for 7th Annual Into the Light Walk for Mental Health

-

Entertainment7 days ago

Entertainment7 days agoMother Fights to Reunite with Children After Kidnapping in New Drama

-

Health1 week ago

Health1 week agoNorth Carolina’s Biotech Boom: Billions in New Investments

-

Entertainment1 week ago

Entertainment1 week agoRed Sox’s Bregman to Become Free Agent; Tigers Commit to Skubal

-

Top Stories1 week ago

Top Stories1 week agoDisney+ Launches Chilling Classic ‘Something Wicked’ Just in Time for October