Top Stories

Tesla’s Ex-Sales Chief Reveals Chinese EV Makers’ Smart Secrets

UPDATE: Jon McNeill, Tesla’s former global sales chief, has just revealed that Chinese electric vehicle (EV) makers employ a “super smart” technique for reusing parts that even Tesla has adopted in its vehicles. This insight is crucial as the EV industry intensifies competition and innovation.

In an interview with Business Insider, McNeill highlighted that Tesla has actively studied competitors, particularly in China, to enhance its own production methods. During his tenure from 2015 to 2018, he noted that Tesla engaged in tearing down Chinese EVs to glean valuable insights, which can now be seen in the design of popular models like the Model 3 and Model Y.

McNeill emphasized that Tesla operates like a “learning sponge,” absorbing and implementing effective strategies from the industry. He specifically pointed out that the reuse of components—utilizing the same parts across different models—has become a hallmark of Tesla’s manufacturing efficiency. For instance, CEO Elon Musk previously stated that approximately 75% of the parts in the Model Y are shared with the Model 3, facilitating easier production ramp-up.

While McNeill did not specify which Chinese models were analyzed, he praised BYD, China’s leading EV manufacturer, for taking parts reuse to unprecedented levels. He stated, “The Chinese engineers are really disciplined about reusing parts underneath the hood that the customer can’t see, and they save a lot of money that way.”

This innovative approach is not entirely new to the automotive industry, as many manufacturers have long utilized shared components across models. However, McNeill noted that Chinese automakers excel in the extent of their reuse, incorporating the same parts down to ancillary components like battery packs and motors. “If you tear down all the BYDs — same windshield wiper motor across all of them,” he explained.

McNeill contrasted this with traditional automakers like Toyota, which often employ entirely different components across their vehicle lineup. “In other words, the guts of a Corolla are almost completely different from a Camry,” he said, highlighting the innovation gap.

The urgency of this revelation cannot be overstated. As the automotive landscape rapidly evolves, the ability to cut costs through strategic parts reuse is crucial for any manufacturer, particularly emerging players in the EV market. McNeill underscored the challenges faced by new automakers, stating, “There’s a reason only one auto company has been started and scaled in the last hundred years, and it’s because it’s really hard.”

Tesla, BYD, and other vertically integrated companies benefit from controlling more of their production processes, allowing them to standardize parts and increase efficiency. Rivian’s CEO, RJ Scaringe, also acknowledged the significance of Chinese manufacturing techniques, noting that his company conducted a teardown of Xiaomi’s SU7 but did not find revolutionary insights to reduce costs.

As the competition heats up in the EV sector, McNeill’s insights highlight the relentless pursuit of efficiency and innovation that defines this industry. With Tesla and other automakers adopting these smart strategies, the future of electric vehicles looks increasingly interconnected and competitive.

Stay tuned for more updates as this story develops, and share your thoughts on how these innovations might reshape the world of electric vehicles.

-

Science1 month ago

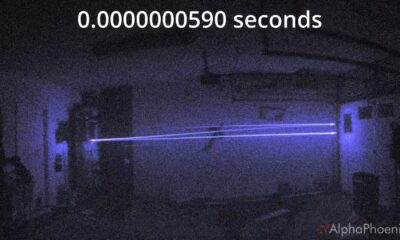

Science1 month agoInventor Achieves Breakthrough with 2 Billion FPS Laser Video

-

Health2 months ago

Health2 months agoCommunity Unites for 7th Annual Into the Light Walk for Mental Health

-

Top Stories2 months ago

Top Stories2 months agoCharlie Sheen’s New Romance: ‘Glowing’ with Younger Partner

-

Entertainment2 months ago

Entertainment2 months agoDua Lipa Aces GCSE Spanish, Sparks Super Bowl Buzz with Fans

-

Entertainment2 months ago

Entertainment2 months agoMother Fights to Reunite with Children After Kidnapping in New Drama

-

Top Stories1 month ago

Top Stories1 month agoFormer Mozilla CMO Launches AI-Driven Cannabis Cocktail Brand Fast

-

Health2 months ago

Health2 months agoCurium Group, PeptiDream, and PDRadiopharma Launch Key Cancer Trial

-

Business2 months ago

Business2 months agoTyler Technologies Set to Reveal Q3 Earnings on October 22

-

World2 months ago

World2 months agoIsrael Reopens Rafah Crossing After Hostage Remains Returned

-

Health2 months ago

Health2 months agoNorth Carolina’s Biotech Boom: Billions in New Investments

-

World2 months ago

World2 months agoR&B Icon D’Angelo Dies at 51, Leaving Lasting Legacy

-

Entertainment2 months ago

Entertainment2 months agoRed Sox’s Bregman to Become Free Agent; Tigers Commit to Skubal