Science

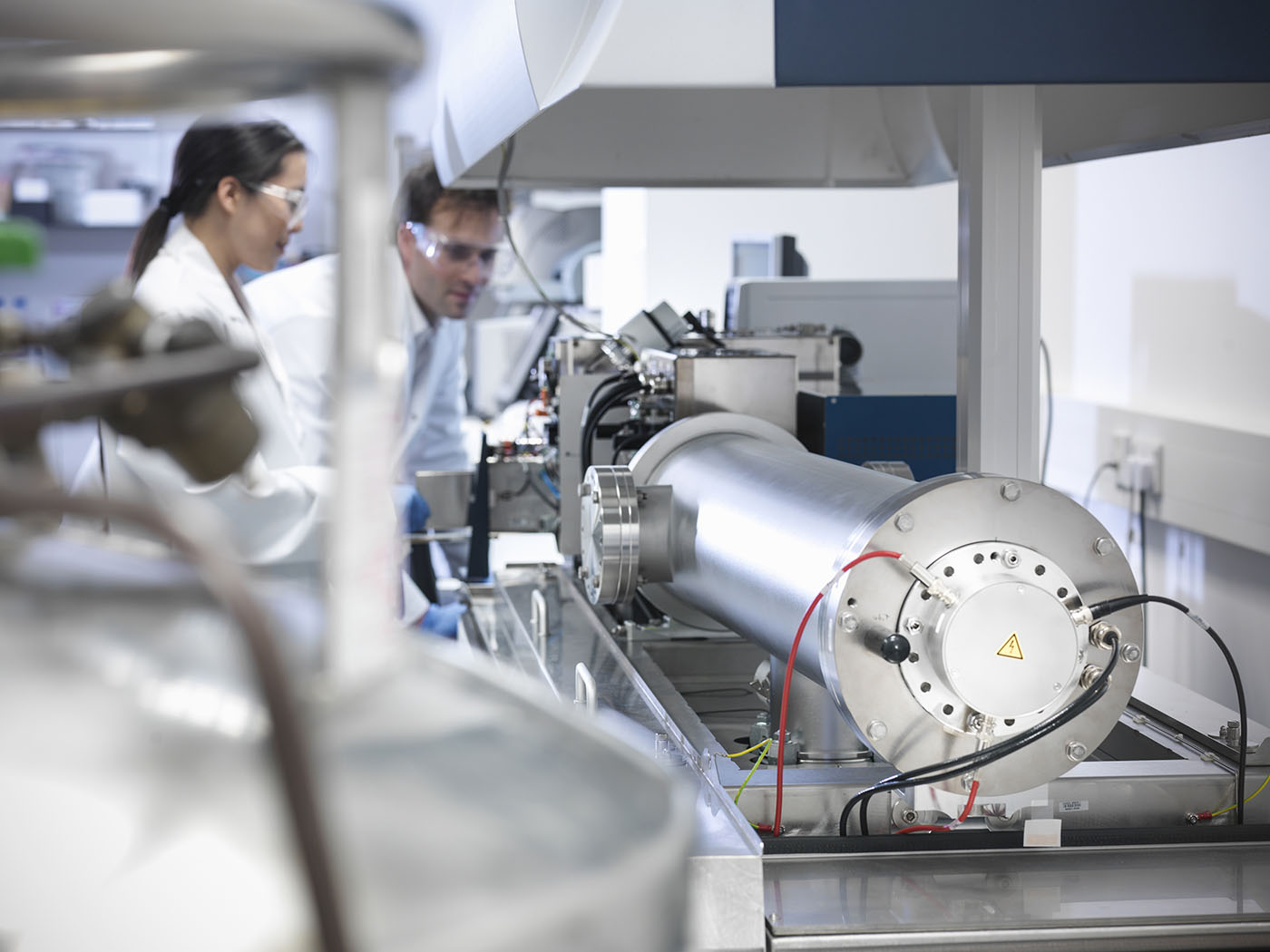

Mass Spectrometry Transforms Biotech: A New Era of Analysis

Mass spectrometry (MS) is undergoing a significant transformation in the fields of biotechnology and biomanufacturing, driven by an expanding array of drug modalities. As the industry embraces innovative therapies such as peptides, siRNAs, mRNA vaccines, and CRISPR components, the need for advanced analytical methods has surged. This evolution presents both challenges and opportunities for scientists striving to ensure the safety and efficacy of modern therapeutics.

Meeting the Analytical Demands

According to Josh McBee, PhD, a mass spectrometry scientist at Advanced Materials Technology, the pharmaceutical landscape is experiencing a renaissance. He describes the recent years as a “golden age” for drug development, highlighting the rapid emergence of various therapeutic modalities, including GLP-1 peptide drugs and mRNA vaccines. However, with this diversification comes the challenge of analyzing complex compounds.

Peptides and RNA are known to degrade rapidly in vivo, necessitating modifications to enhance their stability. These modifications often lead to the generation of synthetic by-products, which must be rigorously separated and characterized. Regulatory requirements further complicate the process, as impurities must be characterized, with standards stipulating that anything above 0.1 percent must be understood and documented. McBee notes, “You can have an impurity up to 0.5 percent in the final product, but anything down to 0.1 percent you need to characterize and understand.”

To achieve the necessary levels of characterization, high-resolution MS and exceptional chromatographic resolution are essential. However, even cutting-edge systems face difficulties when dealing with challenging compounds like oligonucleotides. McBee explains that separating oligonucleotides, especially RNAs and CRISPR guide RNAs, is significantly more complex than working with proteins or peptides. His team is developing superficially porous silica particles to enhance resolving power while managing back pressure.

Despite these advancements, data management has emerged as a hurdle. “The bigger the data sets you collect, the harder it is to maintain your data integrity,” he emphasizes, referring to compliance requirements like 21 CFR Part 11. Consequently, manufacturers are hesitant to implement high-resolution MS in regulated production environments, opting instead for simpler triple-quad and single-quad systems for reliable in-process control.

Addressing Extractables and Leachables

While McBee focuses on therapeutics, Xiaoran Zhang, PhD, a senior scientist at Cytiva, tackles analytical challenges stemming from the materials used in manufacturing. Extractables and leachables (E&L) are compounds that can migrate from production materials into drug products, impacting patient safety and product quality. Zhang explains that a failure to characterize these contaminants could compromise a biologic’s efficacy or introduce toxic substances.

Identification of E&L is particularly challenging due to the complex arrays of oligomers and additives generated by manufacturing materials. Zhang’s team has identified compounds related to BADGE (bisphenol A diglycidyl ether), noting that many derivatives lack reference spectra, complicating identification.

To address these challenges, Zhang’s group has developed targeted liquid chromatography (LC)-QToF workflows utilizing MSe acquisition. This method allows for simultaneous collection of low- and high-energy fragmentation data, expediting the identification process. “This approach significantly reduced identification time and improved confidence in structural assignment,” she states. Zhang envisions the future of impurity analysis as reliant on comprehensive E&L LC-MS databases and artificial intelligence to streamline the identification process.

Real-Time Analysis Innovations

In contrast to traditional LC-MS techniques, Tucker Kitchengs, MBA, from Syft Technologies, specializes in a different analytical approach: selected ion flow tube-MS (SIFT-MS). This technique enables real-time analysis of volatile compounds, eliminating the need for chromatographic separation.

Kitchengs highlights the speed of SIFT-MS, which can analyze residual solvents and nitrosamines within seconds, a stark contrast to the lengthy workflows typically associated with these analyses. The platform is designed for ease of use, requiring minimal training, which is particularly beneficial in fast-paced manufacturing settings.

The capability of SIFT-MS extends into regulatory contexts as well. Syft’s Tracer Pharm11 is the first real-time mass spectrometer compliant with 21 CFR Part 11, developed for nitrite, nitrosamine, and residual-solvent testing. Kitchengs reports early results indicating that nitrite testing can yield results in as little as two minutes, showcasing the technique’s efficiency.

Supercritical Fluid Chromatography

While SIFT-MS exemplifies a minimalist approach, Bill Farrell and Don Nguyen, PhDs at Virscidian, describe supercritical fluid chromatography (SFC) as a highly tunable and selective technique that complements traditional high-performance liquid chromatography (HPLC). SFC utilizes supercritical carbon dioxide combined with organic modifiers, allowing for interactions that facilitate unique separation mechanisms.

Nguyen emphasizes the importance of SFC in achieving enantiomerically pure compounds, highlighting its role in the pharmaceutical industry. The ability to maintain stable chiral columns in supercritical CO2 is crucial, as contamination by the wrong enantiomer can have severe consequences in drug development.

Integrating SFC with MS poses challenges, particularly in managing the gas volumes produced during decompression. Farrell favors atmospheric pressure chemical ionization (APCI) for its compatibility across various molecular classes. Additionally, SFC has sustainability advantages, as carbon dioxide evaporates quickly, minimizing solvent usage and energy consumption.

Looking Ahead

The insights from these experts indicate a field evolving towards a collaborative future rather than competition. The diverse applications of mass spectrometry—including advancements in high-resolution workflows, E&L strategies, real-time testing, and versatile SFC-MS separations—are all vital components addressing the complexities of modern biomanufacturing.

As the landscape of therapeutics grows increasingly sophisticated, the role of mass spectrometry in ensuring safety, efficiency, and innovation will only become more critical. The industry stands on the brink of what could be a new golden age of pharmaceuticals, driven by the continuous evolution of analytical techniques.

-

Science2 months ago

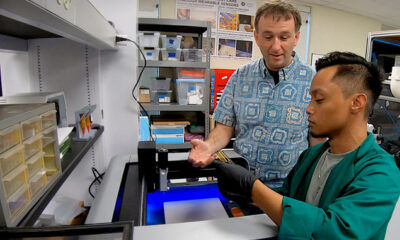

Science2 months agoResearchers Launch $1.25M Project for Real-Time Hazard Monitoring in Hawaiʻi

-

Science4 months ago

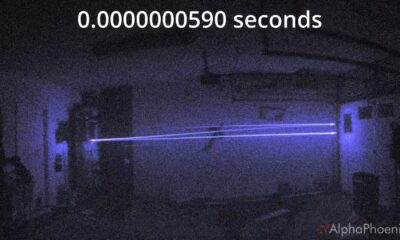

Science4 months agoInventor Achieves Breakthrough with 2 Billion FPS Laser Video

-

Top Stories4 months ago

Top Stories4 months agoCharlie Sheen’s New Romance: ‘Glowing’ with Younger Partner

-

Entertainment4 months ago

Entertainment4 months agoDua Lipa Aces GCSE Spanish, Sparks Super Bowl Buzz with Fans

-

World4 months ago

World4 months agoUK Government Borrowing Hits £20.2 Billion in September Surge

-

Health4 months ago

Health4 months agoCommunity Unites for 7th Annual Into the Light Walk for Mental Health

-

Entertainment4 months ago

Entertainment4 months agoMother Fights to Reunite with Children After Kidnapping in New Drama

-

Entertainment4 months ago

Entertainment4 months agoOlivia Plath Opens Up About Her Marriage Struggles and Divorce

-

Science3 months ago

Science3 months agoAI Gun Detection System Mistakes Doritos for Weapon, Sparks Outrage

-

World4 months ago

World4 months agoR&B Icon D’Angelo Dies at 51, Leaving Lasting Legacy

-

Top Stories4 months ago

Top Stories4 months agoFormer Mozilla CMO Launches AI-Driven Cannabis Cocktail Brand Fast

-

Health4 months ago

Health4 months agoYouTube Launches New Mental Health Tools for Teen Users